Elevating Substrate Analysis with Visual Inspection Verdicts: A MapSuite Solution

Discover the transformative potential of visual inspection verdicts with MapSuite, the ultimate solution for substrate analysis and merging. Seamlessly integrate data from microscopes, automated optical inspection equipment, or manual inspections to create overlay maps that enhance substrate analysis. With MapSuite, you can merge substrate maps with visual inspection verdicts, ensuring defect-free final products and optimizing production efficiency across all types of substrates.

Harnessing Visual Inspection Verdicts for Enhanced Analysis

Visual inspection verdicts, derived from various sources including microscopes and automated inspection equipment like KLA machines, offer invaluable insights into substrate defects and particle presence. By leveraging this data, manufacturers can pinpoint defect areas, classify defects, and fine-tune production processes to bolster yield and product quality.

Introducing MapSuite’s Visual Inspection Integration

MapSuite offers a comprehensive suite of tools and features meticulously crafted to seamlessly integrate visual inspection verdicts into substrate analysis workflows.

Join the MapSuite Revolution

Embark on a journey of enhanced substrate analysis with MapSuite. Elevate your substrate analysis, streamline production processes, and elevate product quality with our cutting-edge tools and features. Whether you’re scrutinizing wafers or leadframes, MapSuite equips you to achieve excellence in substrate analysis and defect mitigation.

Discover MapSuite today and revolutionize your approach to semiconductor and photonics production. Contact us to explore MapSuite’s visual inspection integration capabilities and embark on a journey toward maximizing your manufacturing potentiall.

Key Features of Mapsuite’s Visualization Functionality

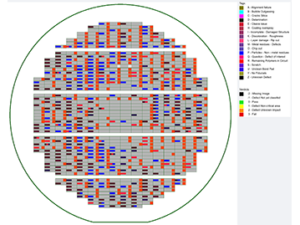

Create Overlay Maps: MapSuite empowers users to craft overlay maps that seamlessly integrate visual inspection verdicts with substrate maps. Witness the distribution of particles, defect areas, and die positions concurrently, facilitating holistic substrate analysis and defect classification.

Merge Capabilities: MapSuite’s robust merge capabilities enable users to fuse substrate maps with visual inspection verdicts, ensuring the exclusion of defect dies from final products. By aligning defect areas with substrate layouts, MapSuite minimizes production waste and maximizes yield.

Defect Classification: MapSuite provides sophisticated tools for classifying defects based on visual inspection verdicts. By categorizing defects according to type, size, and severity, manufacturers can prioritize corrective actions and refine production processes to diminish defects and enhance overall product quality.

Real-time Visualization: MapSuite offers real-time visualization of substrate maps and visual inspection verdicts, empowering users to swiftly analyze and interpret data. With interactive visualization tools, users can zoom in on specific areas, scrutinize edge yield, and identify avenues for process optimization.