Achieve Comprehensive Die Traceability with Transfer Maps and MapSuite

In the intricate journey of substrate manufacturing, achieving die traceability from single wafer dies to final end products is essential for quality assurance and process optimization. With MapSuite, you can leverage transfer maps to seamlessly track die movements across various substrates, supporting wafer and leadframe carriers from initial production stages to final product assembly. Utilizing industry standards like SEMI E142, MapSuite offers an intuitive platform for transfer mapping, enabling manual operations for small quantities or automatic transfer map generation from assembly equipment, ensuring comprehensive traceability throughout the manufacturing process.

Unlocking Die Traceability with Transfer Maps

Transfer maps serve as a vital tool in the quest for die traceability, enabling manufacturers to monitor die movements across substrates and process steps. By leveraging transfer maps, manufacturers can ensure product quality, optimize production workflows, and mitigate risks associated with defective dies or process inefficiencies.

Introducing Transfer Maps with MapSuite

MapSuite is your pathway to efficient transfermaps, ensuring smooth traceability throughout your production process. Elevate your manufacturing standards for high-quality aerospace, automotive, and medical products with MapSuite’s robust features. Whether you prefer automated processes or manual interaction, MapSuite empowers you to achieve impeccable die traceability every step of the way. Experience streamlined operations and elevate your production standards with MapSuite.

Join the MapSuite Revolution

Experience the power of comprehensive die traceability with MapSuite. Enhance product quality, optimize production processes, and streamline traceability operations with our industry-leading solutions. Whether you’re a semiconductor manufacturer, photonics producer, or research institution, MapSuite empowers you to achieve excellence in die traceability and manufacturing efficiency.

Discover MapSuite today and revolutionize your approach to substrate production. Contact us to learn more about MapSuite’s capabilities and start maximizing your manufacturing potential.

Key Features of Transfer Maps in MapSuite

Support for SEMI E142 Standard: MapSuite seamlessly integrates with the SEMI E142 standard, facilitating standardized transfer mapping processes across the manufacturing ecosystem. By adhering to industry standards, MapSuite ensures compatibility and interoperability, enabling smooth data exchange and collaboration among stakeholders.

Comprehensive Substrate Support: MapSuite supports a wide range of substrates, including wafers, leadframes, gel packs, trays, and waffle packs. Whether transferring dies between different substrates or process steps, MapSuite provides a versatile platform for managing die traceability across diverse manufacturing environments.

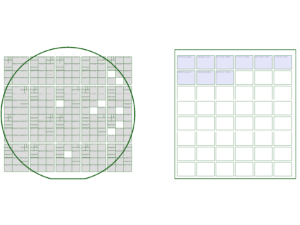

Intuitive GUI for Manual Operations: MapSuite offers an intuitive graphical user interface (GUI) for manual transfer mapping operations. Users can easily visualize die movements, create transfer maps, and track traceability data in real-time, enabling efficient management of small-scale production processes or prototype development.

Automatic Transfer Map Generation: For high-volume production environments, MapSuite integrates seamlessly with assembly equipment to automatically generate transfer maps. By capturing data on die transfers from production machinery, MapSuite ensures accurate and reliable traceability information, minimizing manual intervention and streamlining production workflows.